Core Components Limited is an innovative engineering manufacturer specialising in beer line components such as their range of Fob Detectors and their Automated Core Córas Beer Line Sanitising System which prevents beer waste and over foaming. They are based in Longford, in the Midlands of Ireland. They have developed and patented an automated beer line sanitising system which has novel features facilitating a clean beer line every time a keg is changed.

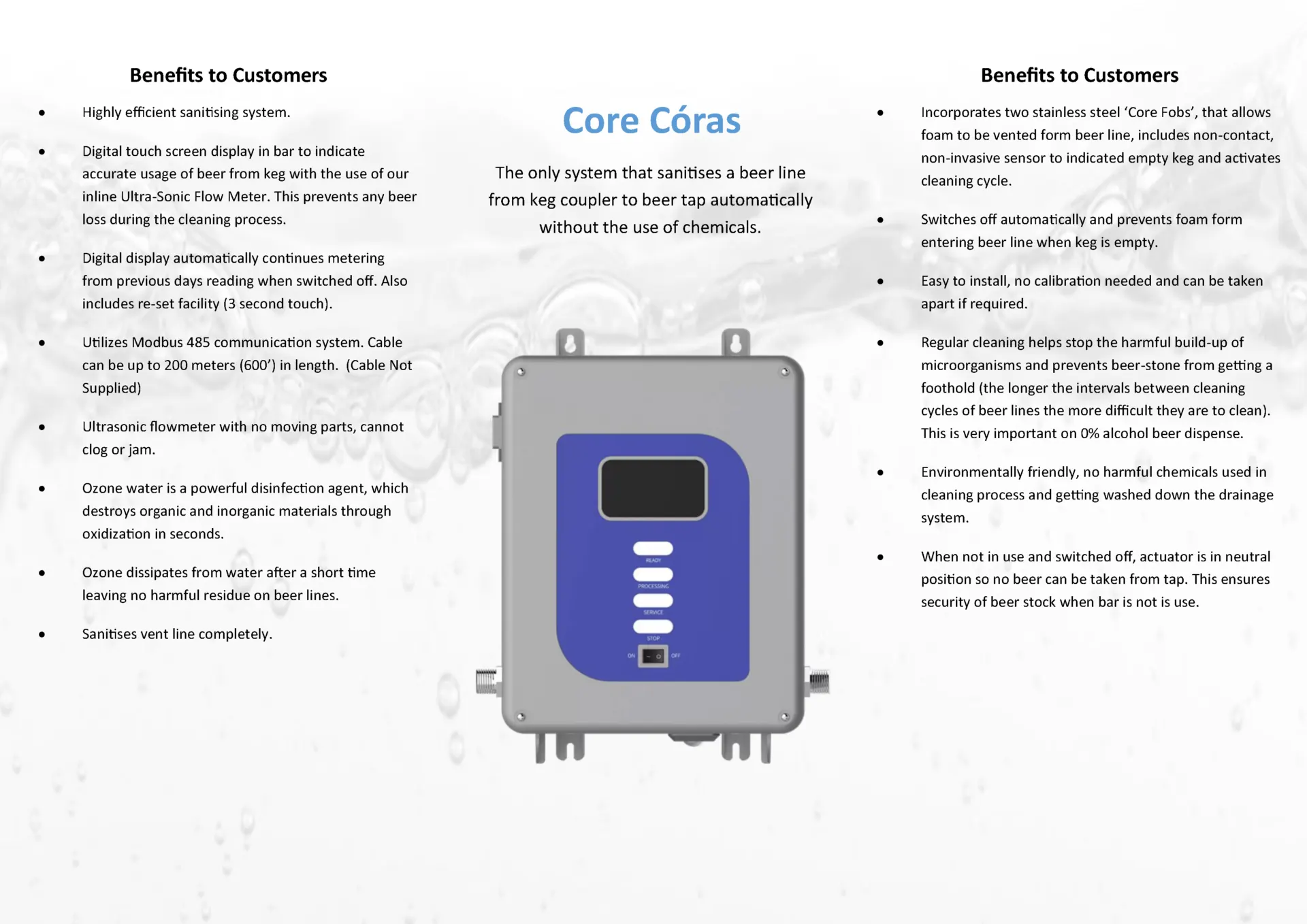

Automated Ozone Delivery System.

Efficient Beer Line Cleaning is Necessary

Beer line cleaning has been a challenge since draught dispense replaced sales of bottles in bars. The issues have been chlorination and taint of nylon lines, discolouration of PVC lines and spoilage due to biofilm build-up. The biggest issue has been contamination of the keg by a dirty tapping head even despite the tapping head having a non-return valve. If the attached beer line is too long the tapping head may drop on the floor. Handling the tapping head with dirty hands is also an issue as the outside of kegs may be contaminated by bird droppings. If rodents and insects are in a cellar, they will be attracted to beer spillage on the tapping head. A simple spray of sanitiser is essential but can be missed easily by the cellarman. When the keg, which is commercially sterile before opening, is connected to an unclean tapping head bacteria and yeasts start growing in the beer. Even with a refrigerated cellar the beer will spoil in three weeks. This is a problem for speciality beers, slow moving craft beers and even occasional dispense (function rooms operated infrequently). Spoilage involves waste and makes all beer including Zero Alcohol and Craft Beer sales uneconomical.

Cloudy beer has become fashionable mainly because smaller brewers were technically unable to filter their lager beer efficiently. Cloud and over hopping of beers disguise “off flavours” but despite the concealment many beers are served where the spoilage can be easily discerned.

Spoilage Causes Waste Making Sales Uneconomical.

Ozone cleaning

Sanitising using ozone is very effective and has been used for many years.

This has been supported by well proven technology, ample published literature about widespread action on bacteria, viruses, yeasts, moulds, and parasites. Improved electrodes allow direct generation of ozone in water avoiding a gaseous phase. Ozone is hitherto used as a terminal sterilant after harsh caustic cleaning. The breakthrough thinking is that ozone when used frequently on a clean line can keep that line in a pristine condition.

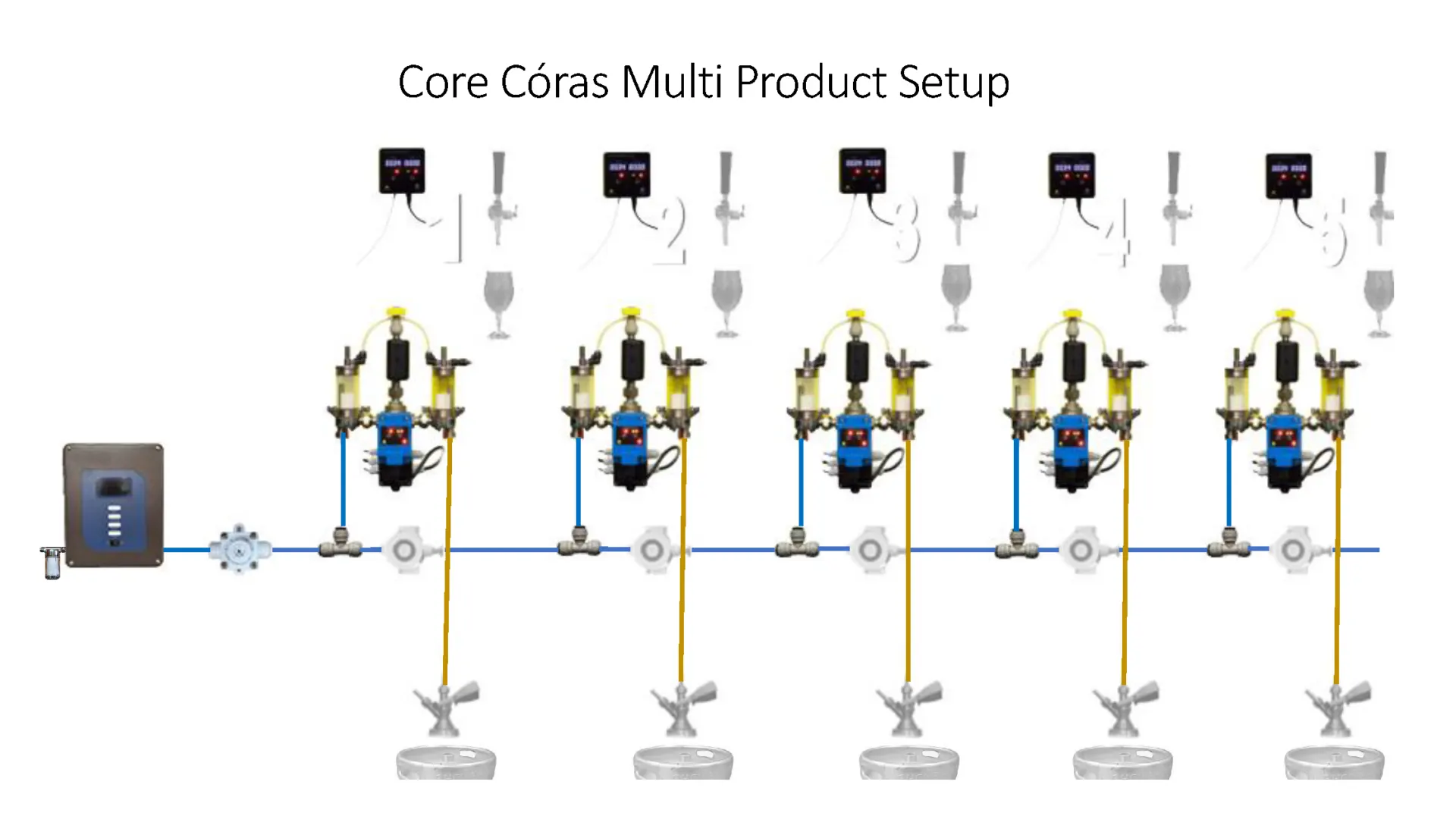

This revolutionary Core Córas Automated Sanitising System combines an advanced ozone generator with automation to make it possible to clean the beer line and tapping head each time the operator changes the keg.

Breakthrough Thinking is that Frequent Sanitisation prevents Biofilm Development.

No Resistance

There is no possibility of development of resistance to ozone as it oxidises the microorganisms and the slime that they produce. As it works it liberates oxygen bubbles which physically disrupt any slime matrix. The only constraints are penetration of any layers and sufficient active agent. Therefore, the system is introduced on a new or thoroughly cleaned beer line. It keeps a new line in pristine condition by preventing establishment of biofilm. No harsh chemical or mechanical cleaning is needed because biofilm is prevented by frequent sanitising and the line remains clean. The ozone is manufactured on site and dispensed directly without storage into the line at the correct time. The ozonated water follows the beer oxidising any organic material on the line and the flow detection prevents the beer being contaminated by the ozonated water. The concentration of ozone is low, and it is inactivated by beer, so the consumer is not at risk. Bar staff are also safe because they are not exposed to any chemical.

Food Safety

While beer is normally regarded as a safe drink there are special circumstances where it can carry illness causing microorganisms. Many small towns and even cities have intermittent boil water notices due to contamination with Cryptosporidium and Giardia. Tropical locations have many more parasites commonly transmitted in water.

Exponential growth of Zero alcoholic beer has been delayed by the difficulty of conventional draught dispense. Alcohol in normal strength beer helps prevent pathogenic bacteria. Unless there is frequent monitoring and cleaning Zero alcoholic beer is high risk.

Zero Alcohol Beer has Particular Dispense Hygiene Hazards.

Niche applications

While the installation is most economical for multiple tap situations the biggest return may be in small remote places. These range from bars on remote islands in the West of Ireland or Scotland where a two-hour boat journey might be necessary to serve a single outlet. Mountain huts in Bavaria or Tyrol reached only by a rough tyre wrecking road also need cleaning to maintain fresh quality beer. Servicing bars on board cruise ships and ferries must be completed during a short turnaround in port or else the service agent is carried on to the next port. These situations are the most expensive taps to maintain in prime condition and even when an average price is negotiated with a contractor the cost remains uneconomical.

Sustainability through Zero Chemicals

The Core Córas Automatic Sanitising System eliminates chemicals such as caustic, chlorine and EDTA and their associated packaging. Waste of beer is eliminated, and effluent is at a minimum. Because of the ozone there are Zero residues in the effluent as ozone reacts with organic material reducing the Biochemical oxygen demand. The biggest improvement in environmental impact is elimination of travel by a service agent especially to remote outlets.